15 de septiembre de 2025

Nutripack llenado & Vigofol 90: Boosting Rice Yields in Nayarit

Effective biostimulation management that makes a difference

Rice (Oryza sativa L.) is one of the most important grains worldwide and a staple for millions of people. However, achieving uniform grain filling and high yields largely depends on efficient foliar nutrition and proper physiological crop management.

At Nutriline Agroscience, we develop solutions that help producers overcome these challenges through biostimulants and specialized nutritional formulations. This approach promotes better nutrient assimilation and increased stress resistance, resulting in higher yields and improved grain quality.

Nutripack Llenado y Vigofol 90 vs. a Commercial Biostimulant

Nutriline’s technical team evaluated the effect of Nutripack Llenado y Vigofol 90 compared to a commercial biostimulant under real field conditions in Villa Hidalgo, Nayarit, a rice-producing area with irrigation and a warm climate.

El objetivo fue medir la respuesta agronómica y el rendimiento final del cultivo de arroz variedad Milagro Filipino, bajo tres tratamientos:

The goal was to measure the agronomic response and final yield of the Milagro Filipino rice variety under three treatments:

- T1: Control, no product application.

- T2: Nutriline Portfolio (Nutripack Grain Filling + Vigofol 90 + HormoLife + AdherPlant + Full-PK + Xtraquel Boro + Nutrifos K).

- T3: Commercial biostimulant.

Applications and Management

Applications were made via aerial spraying during the grain filling and maturation stage, using a mixture of 50 L/ha.

The doses applied per hectare were:

- Hormolife: 250 mL

- AdherPlant: 250 mL

- Full-PK: 1 L

- Xtraquel Boro: 1 L

- Nutrifos K: 1 kg

The commercial biostimulant was applied at 2 L/ha according to the manufacturer’s recommendation.

Results: Higher Yield and Profitability with Nutriline

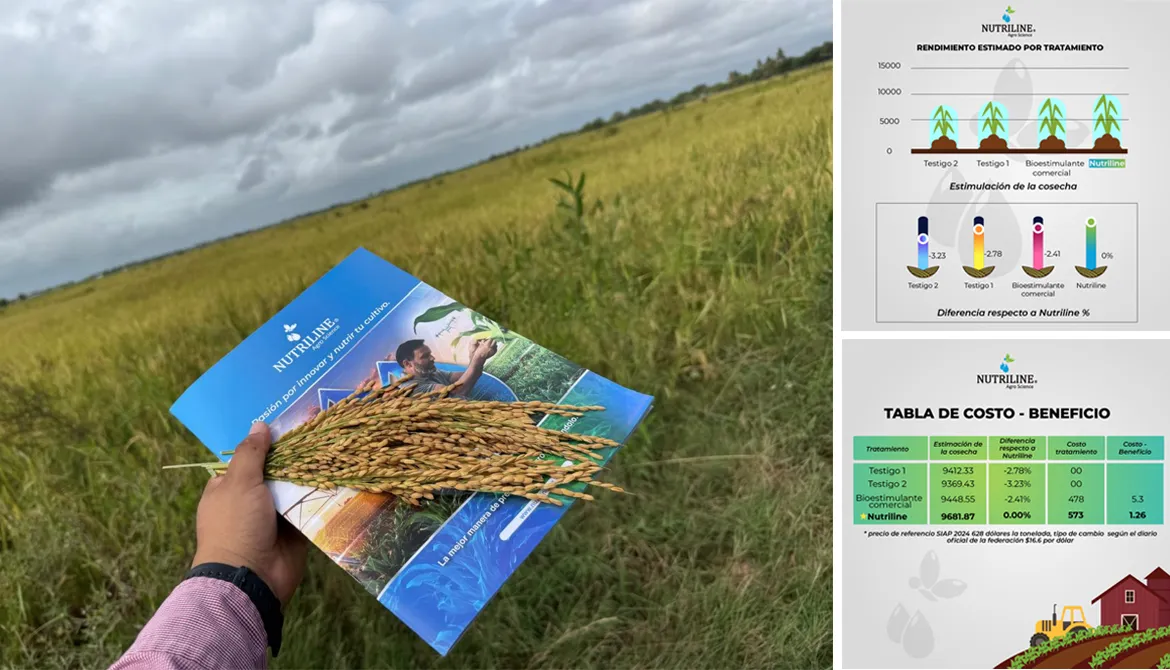

Results showed that the Nutriline treatment achieved the highest estimated yield of 9,681.87 kg/ha, surpassing both the control and the commercial biostimulant treatments, which showed yields 2.4% to 3.2% lower.

|

Treatment |

Harvest Estimate |

Difference vs. Nutriline (%) |

Treatment Cost |

Benefit-Cost Ratio |

|

Control 1 |

9412.33 |

-2.78% |

0 |

|

|

Control 2 |

9369.43 |

-3.23% |

0 |

|

|

Nutriline |

9681.87 |

0.00% |

573 |

5.3 |

|

Commercial Biostimulant |

9448.55 |

-2.41% |

478 |

1.26 |

|

*SIAP 2024 reference price: 628 dollars per ton, exchange rate according to the Official Gazette of the Federation: $16.6 per dollar. |

||||

Nutriline’s formulation showed a superior trend in yield and benefit–cost ratio, reflecting an estimated additional income of $3,033 per hectare compared to the other treatments. This positions us as an efficient and profitable alternative for rice crop nutritional management in the Villa Hidalgo, Nayarit area.

Conclusion

Using the Nutriline portfolio during the grain filling stage in rice demonstrated a better productive and economic response compared to the control and the commercial biostimulant, enhancing both yield and crop profitability.

With a benefit–cost ratio of 5.20 versus 1.26 for the commercial biostimulant, the Nutriline treatment shows greater profitability and agronomic efficiency, establishing itself as a viable and sustainable option to improve rice productivity in Nayarit.

We reaffirm our commitment to farmers, offering real biostimulation, proven results, and profitable solutions that drive productivity in Mexican agriculture.

Compartir